From Guestroom to Lobby: Why Modular Furniture Outperforms Carpentry in Hotels

When you’re investing in a hotel project, every detail reflects your brand. From the lobby lounge to guest suites, furniture isn’t just décor — it’s your reputation in wood, veneer, and polish. The big decision? Traditional carpentry vs. modular furniture.

And here’s the truth: for upscale hotels, modular furniture is quietly becoming the smarter, higher-quality choice.

1. Precision Manufacturing, Zero Guesswork

Carpentry on site is heavily dependent on the skill of the carpenter (and let’s be honest, their mood that day). Dimensions can vary, edges may not align, and finishes often need rework.

With modular furniture, everything is produced in factory-controlled environments using CNC machines and automated edge-banding. The outcome? Perfect sizing, seamless joints, and consistency across every room — whether you’re outfitting 20 suites or 200.

2. Premium Materials, Tested and Certified

Hotels don’t just need “good looking” furniture; they need long-lasting, safe furniture.

Modular systems use engineered boards (like BWR plywood, HDF, MDF) that are pre-tested for strength, moisture resistance, and emissions. Fire-retardant boards and anti-bacterial laminates are also options — features rarely available (or guaranteed) in site carpentry.

3. Speed Without Compromising Finish

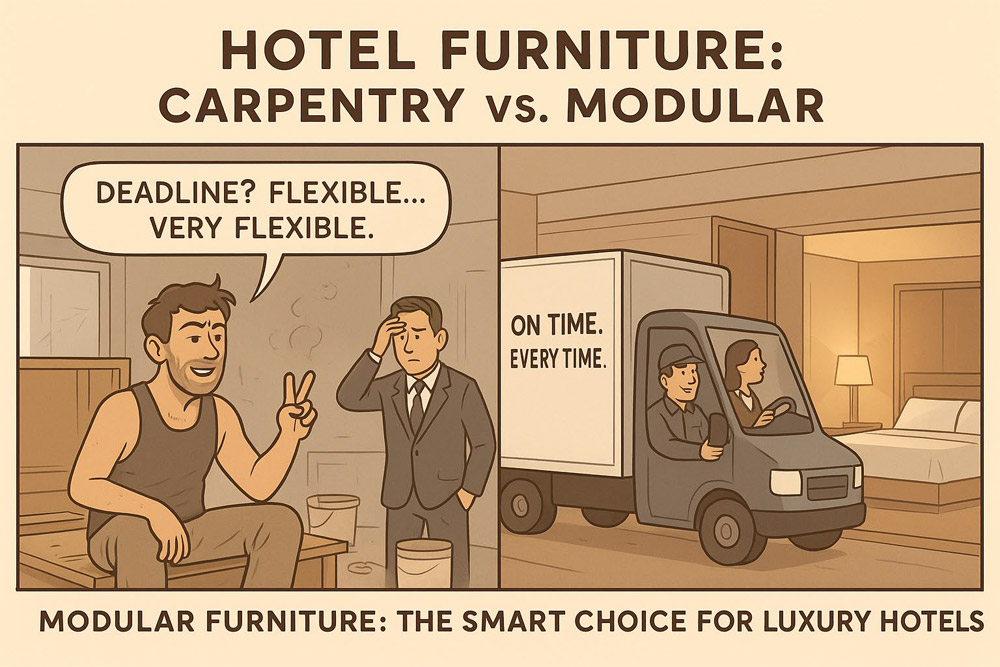

Hotel timelines are brutal. Delays mean lost revenue.

Carpentry work drags on with dust, noise, and unpredictable progress. Modular furniture is manufactured off-site and installed like a system — clean, quick, and guaranteed to meet deadlines. Imagine having an entire floor fitted out in days, not months.

4. International-Level Finishes

Upper-class guests notice details: the uniformity of the bedside tables, the shine on the wardrobe shutters, or the smooth glide of the drawer channels.

Modular furniture comes with factory-applied finishes — UV lacquer, PU polish, membrane pressing — that rival international standards. Carpentry polish, by comparison, is hand-applied, inconsistent, and ages poorly.

5. Smarter Functionality for Guests

From soft-close drawers to integrated lighting, hidden cable management, and modular headboards, factory-built systems allow for guest-friendly features that site carpentry struggles to execute. These aren’t gimmicks — they elevate the guest experience while subtly reinforcing your brand’s luxury quotient.

6. Scalability & After-Sales Peace of Mind

Hotels often expand, renovate, or refresh their interiors. Modular furniture allows exact replication — the same wardrobe from Phase 1 can be manufactured again for Phase 2, years later, with the same finish and quality. Try asking a carpenter to reproduce the same look after a few years — it’s nearly impossible.

Final Word

For upper-class hotels, furniture is not just about filling a room. It’s about consistency, efficiency, and creating a lasting impression on every guest. Modular furniture delivers technical quality that site carpentry simply can’t match — making it the smart investment for hoteliers who value time, brand image, and long-term performance.

So, the next time you’re weighing options, ask yourself: Do you want rooms built on carpenters’ intuition, or on international precision?